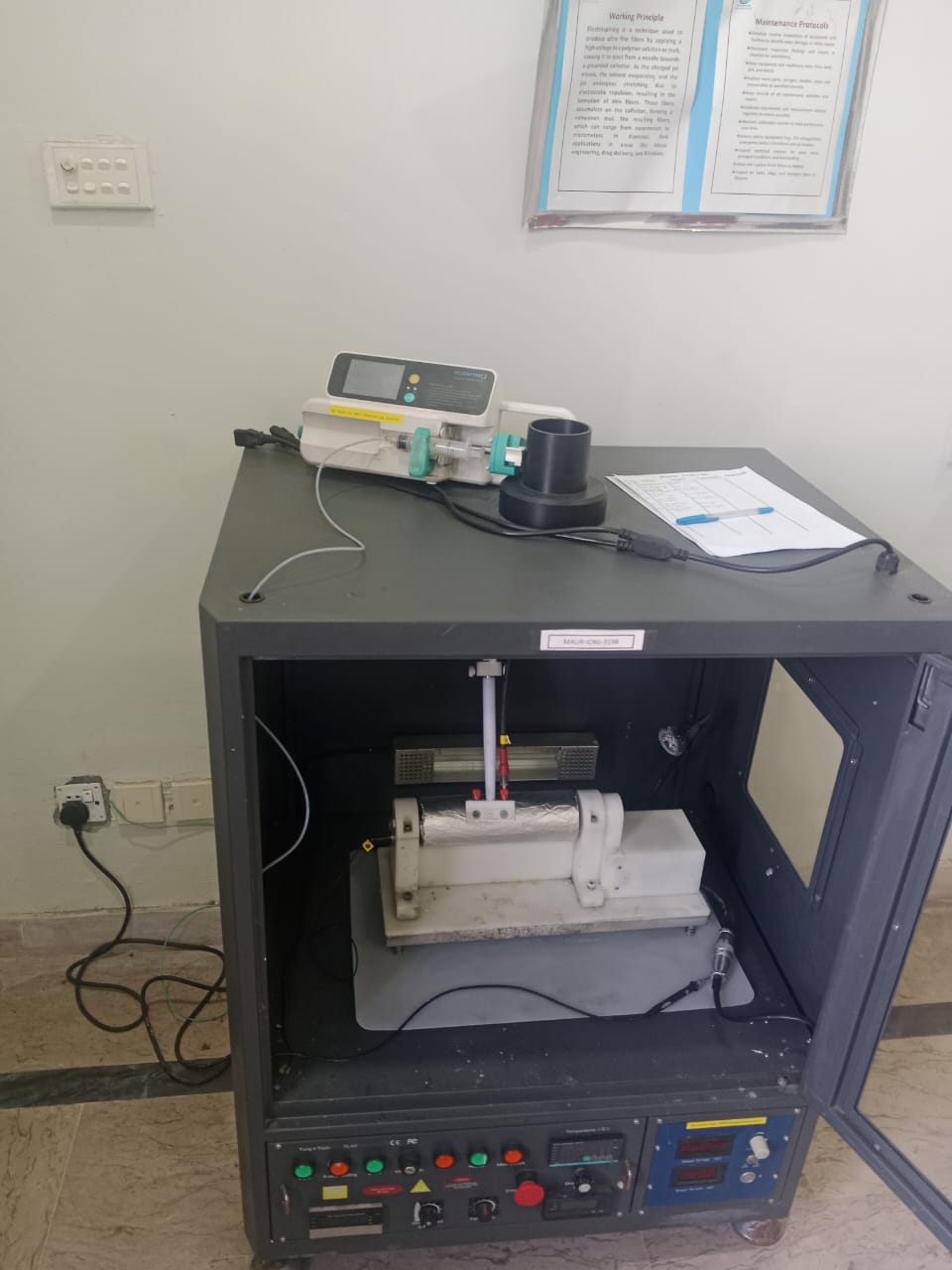

TL-01 electrospinning machine

Available for Inquiry

Interested in this equipment?

Send us an inquiry and we'll provide you with all the details.

Description

Under the influence of an electric field, the high-voltage electrospinning machine uses cutting-edge electrospinning technology to stretch polymer solutions into fine fibers, creating nanoscale or even finer fibers. Filtration, material reinforcement, pharmaceuticals, and textiles are just a few of the industries that use this electrospinning technique to create nanofiber materials with high specific surface area and superior performance.

For teaching and basic spinning experiments, the TL-01 high-voltage electrospinning machine is a simple yet fully functional apparatus. Complete spinning accessories, such as five different kinds of nozzles and yarn collectors, are included, giving users a plethora of options and enabling a variety of experimental combinations.

Technical Specifications

High Voltage Power:

Voltage Range: Typically 0–30 kV DC for electrospinning process application (common for lab models).

High-Voltage Current: ~0.2–0.5 mA max output (typical safety spec).

Voltage Control: Digital display + safety interlocks (standard design).

Syringe Pump / Solution Delivery:

Number of Syringes: Usually 1–2 pumps with independent flow control (basic models).

Flow Rate Range: 0.01–10 ml/h (roughly typical for basic lab electrospinning).

Syringe Compatibility: Common syringe sizes from 1 ml up to 50 ml.

Spinning Parameters:

Spinning Distance: Usually adjustable around 5–25 cm between needle and collector plate.

Collector Type: Plate collector (standard), with optional drum/mandrel available on some versions.

Applications

Biomedical & Healthcare:

Electrospinning technology is widely used in medical and biomedical fields due to its ability to mimic biological structures and support functional tissues:

Tissue engineering scaffolds - nanofiber mats resemble the extracellular matrix, aiding cell growth and tissue regeneration (skin, bone, cartilage, nerves).

Wound dressings - fibers can help maintain a moist healing environment and block microbes.

Drug delivery systems - electrospun fibers can encapsulate drugs for controlled release at targeted locations.

Medical implants & sutures - coatings or biodegradable fibers enhance compatibility with body tissues.

Filtration (Air & Water):

Because electrospun fibers have extremely fine diameters and high porosity, they are excellent for filtering very small particles:

Air filters — high-efficiency particulate capture (including mask materials).

Water purification membranes — remove bacteria, fine particulates, and contaminants due to tight pore structures.

Industrial dust collection and HVAC filters in manufacturing and clean spaces.